Associate Professor Kehai Liu of the Acoustics Materials and Chip Team at the Tsientang Institute for Advanced Study, in collaboration with multiple universities, has published groundbreaking research in Advanced Functional Materials (DOI: 10.1002/adfm.202503432). The team successfully developed an ultrathin graphene oxide-carbon nanotube (GO/CNT) hybrid membrane that overcomes a major limitation of traditional graphene oxide (GO) membranes: their susceptibility to damage under high pressure and their limited flux. This innovation significantly improves nanofiltration efficiency to levels suitable for industrial applications, promising transformative advancements in water treatment, pharmaceuticals, and energy sectors.

The team developed a dual-strategy approach:

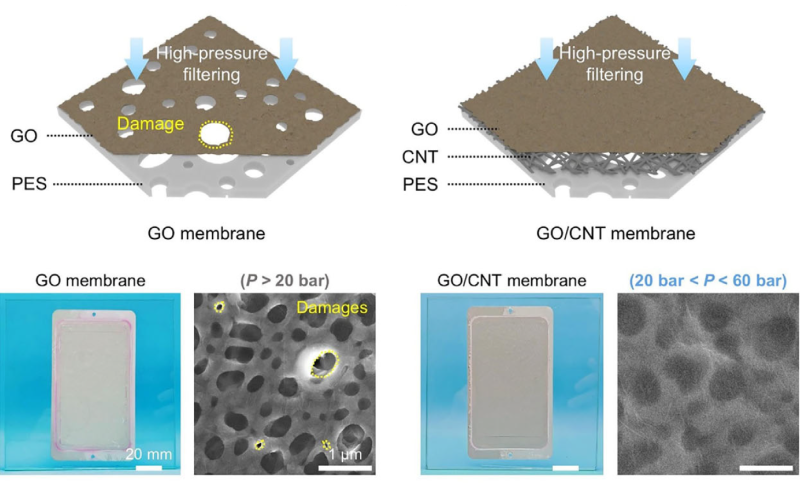

The research team developed a novel layer-by-layer wet-laid fabrication process. By precisely controlling the size of the GO nanosheets (0.81–29 μm) and the CNT loading (0–10 mg·m⁻²), they created a composite structure with a "CNT framework + GO island" architecture (Figure 1). The CNT network, through π–π interactions, supports the GO layers, reducing their free-standing diameter by 65% (from 310 nm to 110 nm) while simultaneously increasing membrane thickness and Young's modulus. This results in a 120%–130% increase in compressive strength.

The resulting composite membranes are ultrathin, measuring only 45–68 nm (one to two orders of magnitude thinner than those previously reported in the literature), significantly reducing manufacturing costs.

Testing demonstrates that the composite membrane, fabricated using the new process, exhibits superior parameters in high-pressure stability, high-efficiency separation, and industrial compatibility.

High-Pressure Stability: The membrane withstands pressures up to 60 bar (compared to 20 bar for typical GO membranes), achieving a flux of 966 ± 96 L·m⁻²·h⁻¹ (Figure 4c). The flux per unit thickness surpasses existing membrane materials by 1–3 orders of magnitude.

High-Efficiency Separation: At 20 bar pressure, the membrane exhibits a rejection rate of >98.7% for dye molecules (such as crystal violet and Congo red) and >90.4% for tea polyphenols (458 Da), with a water flux of 569 L·m⁻²·h⁻¹.

Industrial Compatibility: At 60 bar high pressure, the flux is 45% higher than that of the commercial NF270 membrane, with no swelling or fouling observed after 72 hours of continuous operation.

The research team indicates that this technology has sustainable applications in:

High-efficiency purification of dye wastewater and tea beverages (verified through testing on Oriental Leaf series drinks).

Biopharmaceuticals: Precise separation of small-molecule drugs (e.g., methylene blue, 319.9 Da);

Energy and Electronics: Solvent filtration and purification of battery electrolytes.

The team has optimized the CNT loading using mechanical simulations (COMSOL), paving the way for large-scale production.

Associate Professor Kehai Liu noted: "The GO/CNT composite membrane achieves a synergistic breakthrough in high pressure, high flux, and ultra-thin thickness for the first time, driving nanofiltration technology from the laboratory to industrial applications."